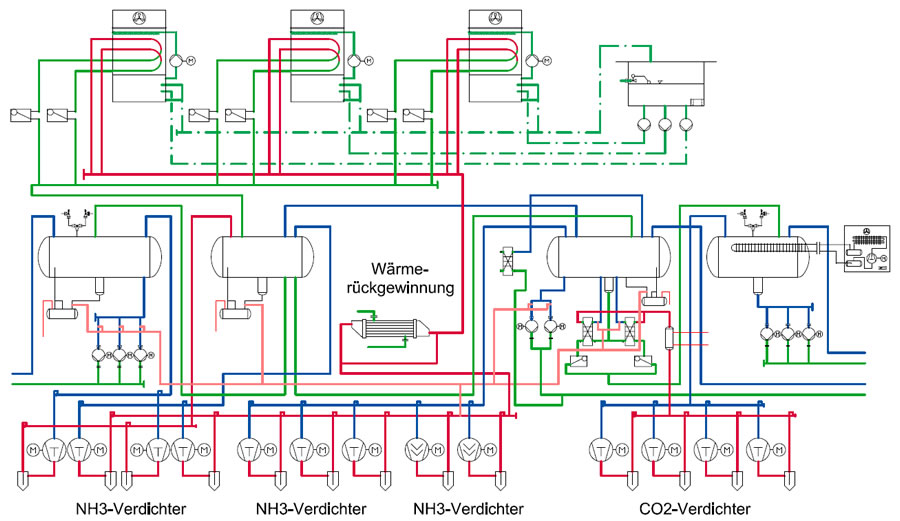

NH3 / CO2 cascade with combined 2-stage NH3 refrigeration system for the cooling supply of various rooms within a logistics center

Currently, deep-freezing of food is more widely used than ever as a method of preservation. It is applied for the long-term storage of food with minimal quality loss and offers the possibility of having a variety of different foods available at any time.

The shorter the distances between freezing, storage, picking, packaging, and transportation, the better the cold chain is secured until the end consumer, and the quality is preserved.

REQUIREMENTS

In the new construction of a deep-freeze logistics center, quick-freezing rooms, freezer storage, and temperature-controlled picking rooms are integrated into one building, so that transportation distances are kept as short as possible.

The ARCTOS refrigeration system meets the varying refrigeration demands of the different areas within the deep-freeze logistics center. Great importance is placed on energy efficiency, maximum energy savings, and heat recovery.

In the selection of refrigerants, natural refrigerants with ecological sustainability and high volumetric cooling capacity were consciously chosen.

FREEZING ROOMS

Quick-freezing or freezing rooms are used to rapidly freeze products in large quantities (on pallets). This shock freezing or freezing takes place within a few hours, depending on the initial temperature and quantity (pallet size approx. 1.2 x 0.8 x 1.5m).

In this process, the product's cellular structure remains intact, and only very small ice crystals form. The rapid freezing process, often done directly in the packaging, thus serves to preserve the freshness of the product.

| Refrigerant: | NH3 (R717) |

|---|---|

| Refrigerant quantity: | 5,700 kg |

| Cooling capacity Q0: | 2,230 kW (-10° C) 736 kW (-36° C) |

| Maximum allowable operating pressure: | 13 /16 /23 bar (LP / MP / HP) |

| Evaporation temperature NH3: | -3.5 / -10 / -36° C |

| Condensation temperature NH3: | +32° C |

| Condenser capacity: | 3x 1,372 kW |

| Refrigerant: | CO2 (R744) |

| Refrigerant quantity: | 3,500 kg |

| Cooling capacity Q0: | 4x 198 kW (-49° C) |

| Maximum allowable operating pressure: | 25/ 40 bar (LP/HP) |

| Evaporation temperature CO2: | -49° C |

| Condensation temperature CO2: | -7° C |

| Condenser capacity: | 2x 580 kW |

PRINCIPLE

Through the CO2 / NH3 cascade refrigeration system built by ARCTOS, with a combined 2-stage NH3 compression refrigeration system, the various areas within the deep-freeze logistics center are supplied with different temperatures.

The evaporator of the upper cascade stage (NH3) also serves as the condenser for the lower cascade stage (CO2).

The liquid CO2 supplies the four high-performance shock freezers with a total freezing capacity of 264 pallet spaces at a vaporization temperature of -49° C, based on a CO2 separator with pump operation, at a room temperature of -42° C.

The refrigeration supply for the two deep-freeze halls with a total volume of 80,000 m3 and the deep-freeze handling area (room temperature of -26° C) is provided by the two-stage NH3 compression refrigeration system.

This system features an LP separator and two MP separators. The evaporation of NH3 takes place at -36° C, and the supply to the freezer storage is achieved through pump operation.

The refrigeration supply for all temperature-controlled rooms between 0° C and +7° C is provided by the upper cascade stage (NH3) of the freezer cascade refrigeration system, also using a pump circulation system at an evaporation temperature of -10° C.

HEAT RECOVERY

To achieve the highest possible energy efficiency, heat recovery is operated via a desuperheater in the NH3 pressure line. The waste heat used for office heating is temporarily stored in a buffer tank.

NATURAL REFRIGERANTS – A SENSIBLE CHOICE DESPITE CERTAIN RISKS

There are refrigerants of various toxicity levels – what matters is how one warns of a leak into the environment and protects themselves thereafter.

Since this is technically feasible, the disadvantages of NH3 and CO2 should not be a criterion for excluding their use in refrigeration systems.

Especially since these refrigerants are also used because of their good environmental performance. Both refrigerants are natural and ecologically sustainable, with a high volumetric cooling capacity, and are cost-effectively available.

Therefore, they are ecologically and economically sensible and of great importance for climate protection.

R717 (NH3, AMMONIA)

The synthetically produced R717 is a pressurized liquefied gas with a pungent odor. The fact that R717 has no ozone depletion potential (ODP=0), no direct greenhouse effect (GWP=0), and high energy efficiency makes it an ecologically optimal refrigerant.

Due to its very large specific evaporation enthalpy, a relatively small amount of refrigerant is required in relation to the cooling capacity.

The optimal application range as an evaporating refrigerant extends from +10° C to -45° C in the cooling range and from +50° C to +90° C in the heat pump range.

Ammonia is mildly flammable and difficult to ignite. Leaked refrigerant is quickly detected by its characteristic pungent odor at very low, non-harmful concentrations. Gas warning systems provide alerts to protect against the harmful effects of leaking NH3.

R744 (CO2, CARBON DIOXIDE)

The natural refrigerant CO2 is ecologically and safety-wise an ideal refrigerant, which can be excellently used in the low-temperature range.

The optimal application range as an evaporating refrigerant extends from -20° C to -52° C in the subcritical range. It is non-toxic, non-flammable, has no ozone depletion potential, is chemically inert, inexpensive, and allows for compact design due to its low volumetric flow.

Leaked CO2 gas is heavier than air and can accumulate in lower areas of enclosed spaces. Gas warning systems provide alerts to protect against the suffocating effects of leaking carbon dioxide.

Since liquid CO2 expands significantly when heated, the high shut-off pressure (at +25° C, 63.4 bar(g)) must be considered in the design. This can be technically addressed, for example, through a shut-off unit or an expansion vessel.