Mobile brine cooling system in a special container, designed as a CO2 / NH3 cascade refrigeration system and equipped with piston compressor units.

To avoid the problem of infiltrating groundwater in deep construction projects, ground freezing of underground areas is often used.

ARCTOS offers the possibility to freeze the soil around or above the construction site with its ground freezing units. The ice shield protects the construction site from groundwater infiltration during the construction period and provides static reinforcement.

Date: 04/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Construction Industry & Ground Freezing

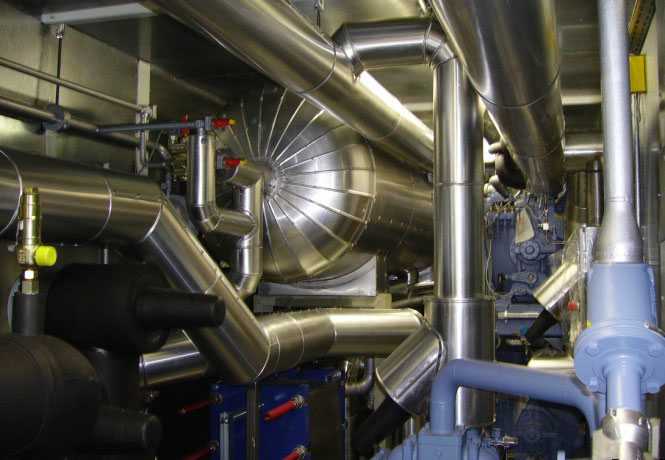

Special Container with Ground Freezing Unit

The mobile brine cooling system is installed in a special container and equipped as a cascade refrigeration system with piston compressor units.

The refrigerants used are NH3 in the lower and CO2 in the upper cascade stage. The CO2 / NH3 cascade refrigeration system is used for cooling a brine (CaCI2, 30%).

This is used for freezing the ground (frozen mass), including for the creation of tunnel boring cross sections.

The chosen design as a cascade refrigeration system was selected to allow for deeper cooling if necessary. However, a different coolant carrier is required for this. The cooling limit for TYFOXIT F 50 is -50 °C, compared to approximately -45 °C for 30% CaCl2.

Ground Freezing

From a pilot tunnel drilled specifically for this purpose (see above), the refrigerant, cooled to -45 °C, is directed to the ground freezing location with the help of freezing lance units (see below).

Once a calculated volume of soil has been frozen, construction work can begin.

During this process, the above-ground refrigeration system continuously continues to freeze the ground.

After the work is completed, a concrete shield, for example, protects the underground cavity (e.g., tunnel, shaft).

Why a Cascade Refrigeration System?

The cascade refrigeration system is often used when low temperatures need to be generated economically.

In this setup, a low-temperature refrigerant (e.g., CO2) is used in the lower cascade stage's cycle.

The evaporator of this stage acts as the condenser for the upper cascade stage, which contains a different refrigerant (e.g., NH3).

Thanks to the well-matched evaporation and condensation properties, low temperatures and favorable pressure conditions for the compressors can be achieved.

| Refrigerant: | NH3 (R717) / CO2 (R744) |

|---|---|

| Refrigerant Quantity: | Max 100 kg NH3 / max. 200 kg CO2 |

| Cooling Capacity Qo: | 275 kW |

| Brine Inlet tS1: | -33° C |

| Brine Inlet tS2: | -38° C |

| Brine Flow: | 57.3 m³/h |

| Cooling Medium: | Water/Air |

| Water Inlet tS3: | +27° C |

| Water Outlet tS4: | +31° C |

| Compressor Manufacturer: | GEA Grasso |

| Compressor Type: | Piston Compressor |

| Machine Container: | 40'-Container for the brine cooling unit, pumps, and electrical control panel / switchgear room |

Date: 04/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Construction Industry & Ground Freezing