2-stage NH3 refrigeration system with intermediate expansion for direct cooling of six production lines and cold brine or ice water generation

In the food industry, modern refrigeration systems face complex demands, especially regarding efficiency and operational reliability. ARCTOS offers the necessary expertise as a competent and reliable partner, backed by years of experience in industrial refrigeration system construction.

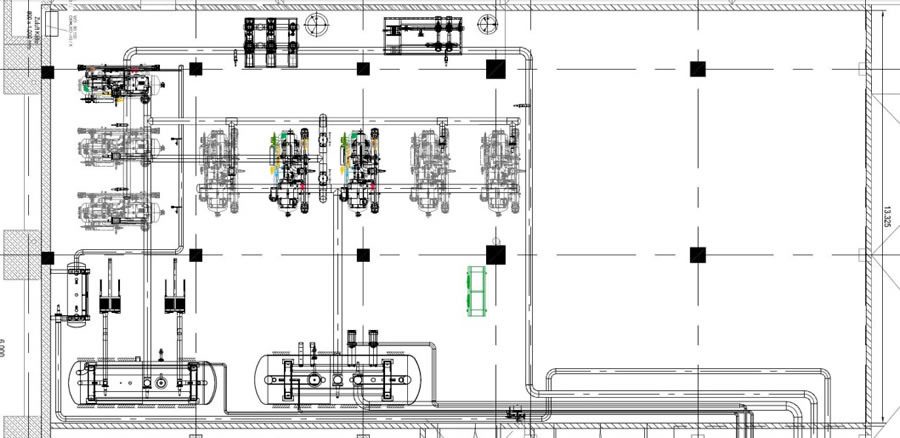

Concept for Refrigeration Supply

A new refrigeration plant has been built in the basement of the factory for the expansion of the pasta production.

The production cooling for six lines is carried out using NH3 direct evaporation (pump operation). The air handling units (AHUs), ice water cooling, and machine and switchgear room cooling are supplied with cold via a glycol circuit.

The cold brine is generated through two heat exchangers, each with 800 kW, in a natural circulation loop.

In the machine room, the components for heat recovery (HR) are also integrated via the oil cooling of the compressors (heat exchangers, pumps). The NH3 pressurized gas is used for defrosting the coolers and condenses in evaporative coolers on the roof.

| Kältemittel: | NH3 (R717) |

|---|---|

| Kältemittelmenge: | 8.000 kg (1. BA 2016: 4.750 kg) |

| Kälteleistung Q0: | ca. 2.000 kW bei -25° C, ca. 1.800 kW bei -3° C |

| Höchstzulässiger Betriebsdruck: | 13 / 16 /23 bar (ND / MD / HD) |

| Verdampfungstemperatur: | -25° C / -3° C (ND / MD) |

| Kondensationstemperatur: | +32° C |

| Kühlmedium: | Luft / Wasser |

| Kaltsoleerzeugung: | 1.600 kW bei -1 / +6° C, 2x PWT mit je 800 kW |

| Kälteträger: | 30 Vol.% Propylenglykol |

| Wärmerückgewinnung: | ca. 400 kW |

| Verdichterfabrikat und -typ: | Mayekawa 4x N200 VMD-HE (ND) 1x N200 VMD-HE (Swing) 3x N160VMD-LE (HD) |

Design

Each of the six production lines is designed for a product throughput of up to 3,000 kg/h at -25° C evaporation. This corresponds to approximately 340 kW cooling capacity per line (total approximately 2,040 kW).

To ensure these capacities, the system has been designed with redundant components (including swing compressors for ND and HD operation, as well as pumps).

For efficiency improvement, each compressor and pump is equipped with frequency converters.