10 NH3 refrigeration systems with a total of 4.5 megawatts of cooling capacity

Due to the rapidly growing world population, increasing prosperity in emerging countries, and changing dietary habits, there is a constant demand for growing productivity in the agricultural sector.

This productivity cannot be met with conventional methods anymore, and the need for mineral fertilizers (including potash) is constantly rising.

The often difficult-to-access potash deposits are primarily extracted in mines. Here, freeze shaft construction technology is frequently used.

Date: 11/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Construction Industry & Ground Freezing

The potash mine, for which ARCTOS delivered 10 NH3 refrigeration systems in container construction to Russia, has a final depth of nearly 1,200 meters.

The freeze shaft depth is at 520 meters, and the clear diameter of the shaft is 7 meters. After completion of the shaft drilling, the annual output of potassium chloride is expected to be approximately 2.3 million tons.

PRINCIPLE OF FREEZE SHAFT CONSTRUCTION TECHNOLOGY

The above-ground NH3 refrigeration systems are used to cool Tyfoxit F50®, which is applied in earth freezing.

For this purpose, freeze drill holes are drilled deep into the soil to be frozen and are supplied with brine. The brine, cooled to -38° C, freezes the ground around the freeze drill holes.

Construction work can thus proceed without the risk of static damage and without the infiltration of groundwater and surface water. After the construction activities and freezing phase are completed, the refrigeration system can be relocated to another site due to its container construction.

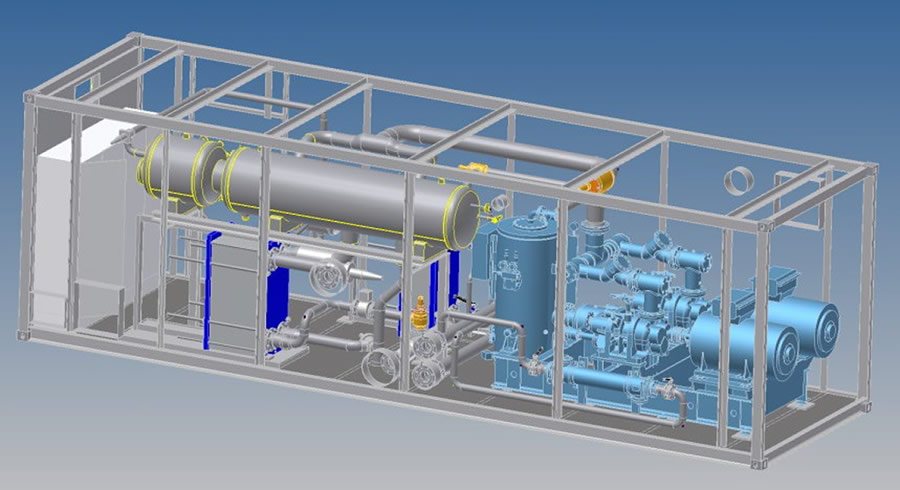

The 10 NH3 refrigeration systems were executed as transportable container units with compressors in two construction forms.

| Refrigerant NH3 | (R717) |

|---|---|

| Refrigerant quantity | each 200 kg |

| Cooling capacity Q0 | each 450 kW |

| Maximum permissible operating pressure | 13.0 / 16.0 / 23.0 bar (Low pressure / Medium pressure / High pressure) |

| Evaporation temperature | -41° C |

| Brine Tyfoxit | F50® |

| Brine inlet t1 | -33° C |

| Brine outlet t2 | -38° C |

| Condensation temperature | +35° C |

| Cooling medium | Water |

| Water inlet t3 | +26° C |

| Water outlet t4 | +31° C |

| Compressor manufacturer and type | GEA-Grasso Double and single screw units |

NH3/CO2 - CASCADE REFRIGERATION SYSTEM WITH BRINE TEMPERATURES DOWN TO -45° C

To minimize failure risks, the brine circuit was designed with dual configurations. The prefabrication of the 10 units and the pre-insulated piping network was carried out at the Sörup plant. Due to this maximum level of prefabrication in Germany, the refrigeration systems with brine piping were assembled and commissioned on-site in the shortest time possible.

ON-SITE INSTALLATION

The image shows the brine piping outside the refrigeration containers. Behind it is the pump house, where the brine pumps, tanks, and piping are integrated. The 3D planning and pre-assembly were carried out by ARCTOS in Sörup.

ADVANTAGES OF CONTAINER DESIGN

ARCTOS has already built a variety of container systems, in which prefabricated base frame units, known as units, were installed. The container design offers the operator a number of advantages:

- Flexibility regarding the installation location

- No space requirements within the buildings when installed outdoors

- The system is weather-protected

- Construction work is carried out at the manufacturer's facility in Sörup (cost reduction for outdoor installations)

- TÜV inspections are carried out at the Sörup plant, with final inspection at the installation site

- In case of an emergency, the refrigerant will not enter the building, and the container serves as containment. It is possible to equip it with an NH3 absorber.

Certification

The requirement for ARCTOS was the certification of the refrigeration systems for import and operation in the Russian Federation.

A GOST-R certification (conformity of the export product with Russian quality standards and regulations) was obtained, as well as a RosTechNadsor certification (operating permit for the use of technical equipment in Russia).

Date: 11/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Construction Industry & Ground Freezing