Single-stage Propene refrigeration system in container design

Natural gas extracted from natural reserves contains unwanted components that must be separated. This is done through cooling. As long as the pressure of the extraction site is large enough, the cooling of the natural gas can be achieved through the Joule-Thomson effect.

If the pressure is no longer large enough, a refrigeration system, known as a Cold-Frac system (CFA), can take over this cooling.

ARCTOS Industriekälte AG builds CFA refrigeration systems that, according to customer specifications, meet the different requirements regarding performance demand and temperature levels.

Refrigerant

The natural refrigerant propene (R1270) is used in the system presented below. Since the refrigeration plants are designed for use in a gas field according to the operator's explosion zone plan, no additional measures are required for the use of the flammable refrigerant.

In the propene refrigeration system, the gas cooling requires an evaporation temperature of the refrigeration system of approximately -10°C to -30°C.

A single-stage R1270 refrigeration system is sufficient for this temperature range. For lower temperatures, two-stage systems are required, which have also been implemented by ARCTOS. ARCTOS provides the plant control in Siemens S7 or integrates the refrigeration system control into the customer's control system.

| Refrigerant: | R1270 (Propene) |

|---|---|

| Refrigerant quantity: | 210 kg |

| Cooling capacity Q0: | 30 kW |

| COP value: | 1.94 |

| Maximum allowable operating pressure: | 25/25 bar (ND/HD) |

| Evaporation temperature: | -24° C |

| Condensation temperature: | +40° C |

| Compressor manufacturer: | Sabroe HPO W4 |

| Compressor type: | Piston cylinder, four cylinders including VFD operation |

| Condenser: | Air-cooled condenser with four speed-controlled fans in V-shape |

E-ROOM

The electrical room (E-room) for the refrigeration system was implemented by the customer. Solutions where the E-room is integrated into the container can also be realized by ARCTOS. Programming is done according to the requirements.

CONTAINER DESIGN

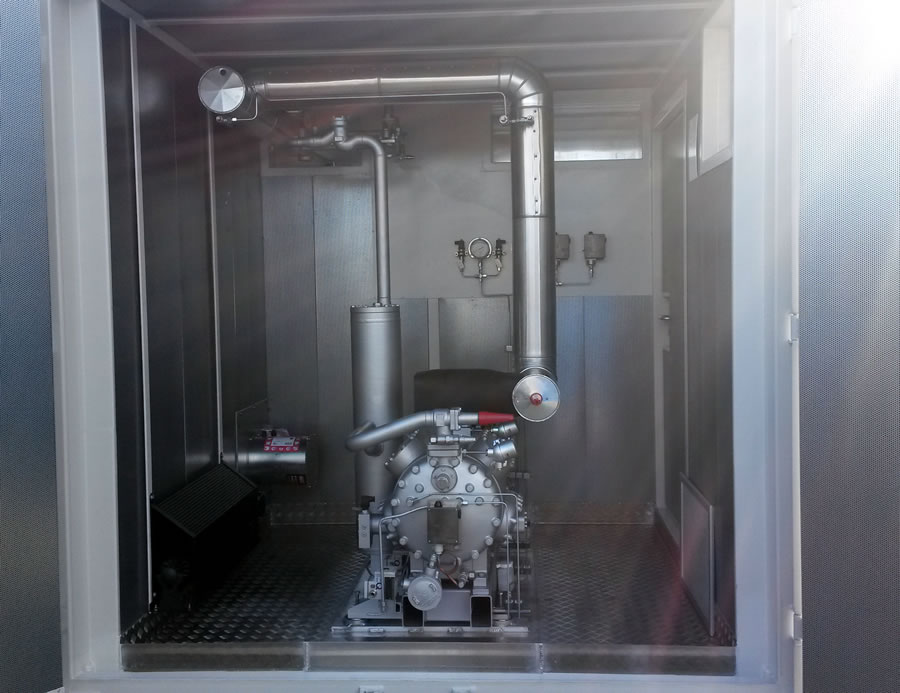

The system is executed in two parts: A specialized container contains the compressor, the high-pressure collector, and the condenser. The compressor itself is located in the machine room of the container.

Compression is performed by a frequency-controlled 4-cylinder piston compressor. With an evaporation temperature of -24° C and a condensation temperature of +40° C, the compressor can provide a cooling capacity of 30 kW.

The compressor type used from the manufacturer SABROE can also be delivered in the same size with eight cylinders, thus with double the capacity, or in a different size with four times the displacement volume.

The entire container system was manufactured at the factory in Sörup. The final assembly and wiring of the remaining parts of the refrigeration system were carried out on the gas field.

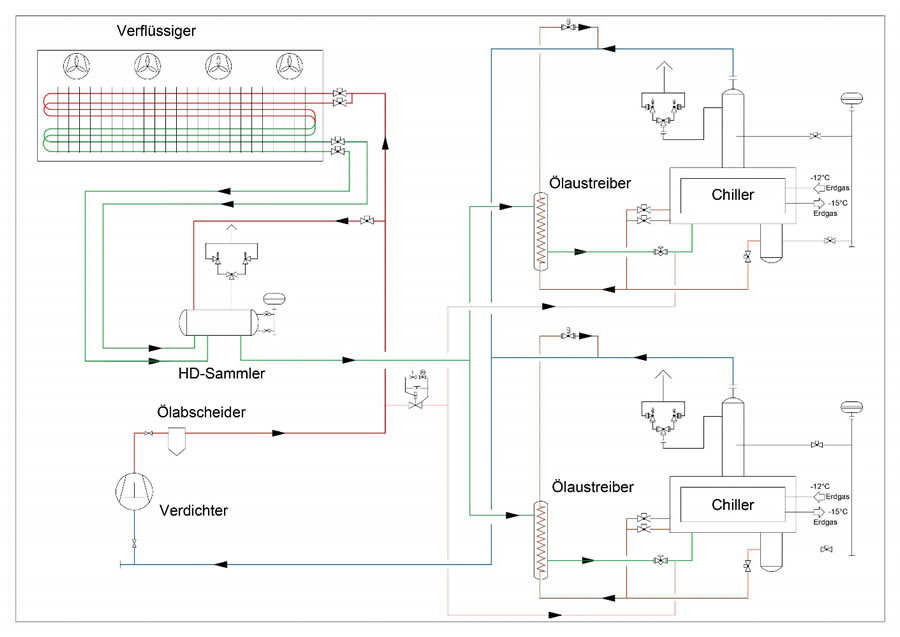

As shown in the simplified P&ID diagram, this includes the two expansion valves and the evaporators (chillers) of the refrigeration system.

The evaporators are fully welded plate heat exchangers, which have an allowable operating pressure of 84 bar. The refrigerant evaporating in the plate heat exchangers extracts energy from the natural gas, thereby cooling it.