Often, the machine room for refrigeration systems in industrial buildings is limited, or the system is required to be located outside the building for safety reasons. In such cases, ARCTOS Industriekälte AG offers the option of delivering the refrigeration system in a compact container design.

The expertise of ARCTOS Industriekälte AG is based on the construction of numerous container systems, in which prefabricated base frame units, known as units, were integrated.

POSSIBLE DIMENSIONS

When choosing the container, standard dimensions of a shipping container can be used, or custom-made designs can be ordered as needed.

The external dimensions should not exceed 12.2 x 3.0 x 3.2 m (L x W x H); otherwise, special transport permits and possibly escort vehicles may be required for transportation.

It is also important to consider the country-specific maximum weight (including vehicle) for transportation.

ADVANTAGES OF BUILDING A REFRIGERATION SYSTEM IN A CONTAINER

ARCTOS Industriekälte AG builds container systems with units in modular construction form, offering a variety of advantages:

- Flexibility in installation

- No space required inside the building

- Weather protection for the system

- Cost reduction due to construction work in the manufacturer’s plant in Sörup

- Protection against refrigerant leakage into the building in case of failure

- Custom design of the container (machine room)

Prefabricated base frame units – UNITS

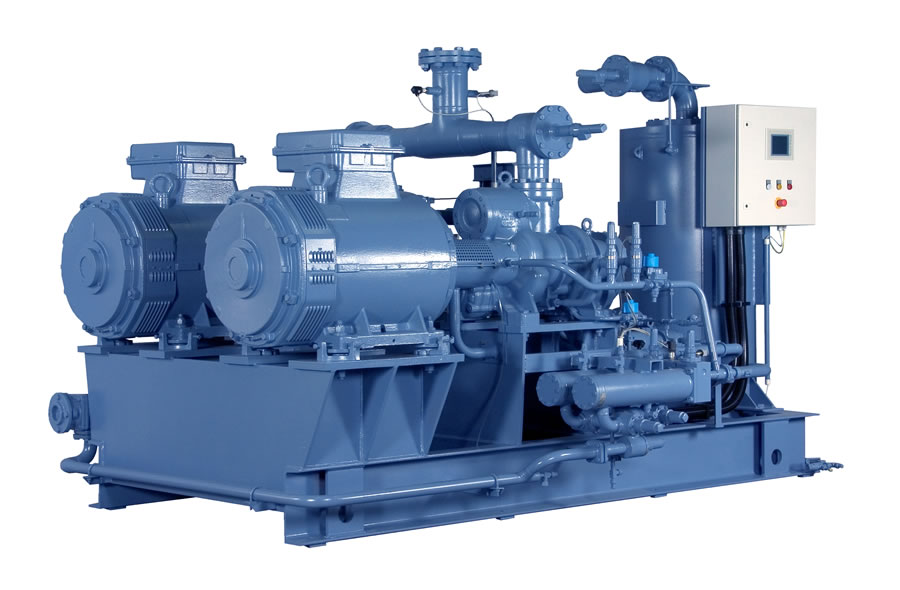

Since the refrigeration system in container form will travel at least once after construction, ARCTOS primarily uses prefabricated base frame units, known as units. They offer high stability and durability and are delivered ready for installation.

| Standard Container | High Cube | Special Container | |

|---|---|---|---|

| Length | 6.058 m / 12.192 m (20' 4" / 40') | 6.058 m / 12.192 m (20' / 40') | 12.2 m |

| Width | 2.44 m (8') | 2.44 m (8') | 3.0 m |

| Height | 2.591 m (8' 6") | 2.90 m (9' 6") | 3.2 m |

| Max. Total Weight | 24,000 kg / 30,480 kg | project-dependent | project-dependent |

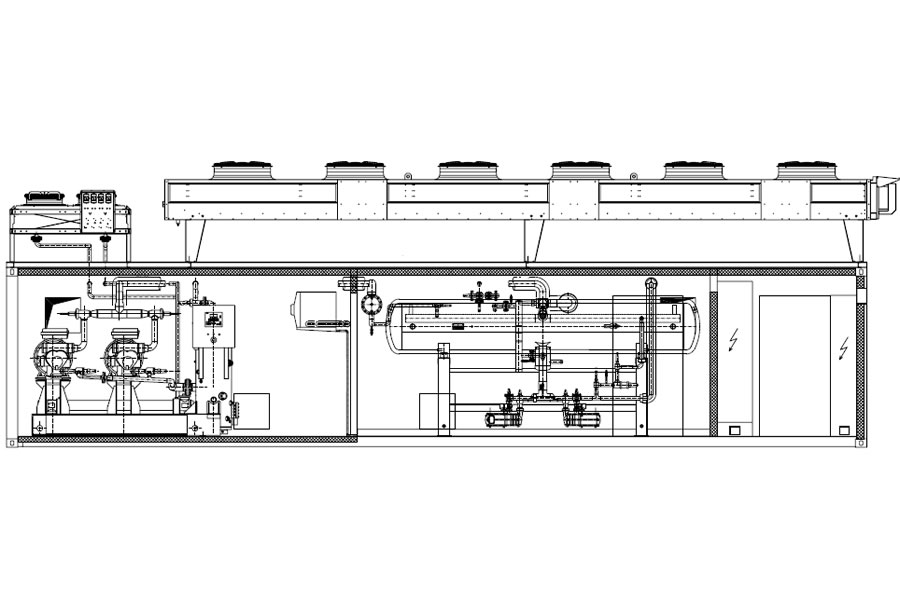

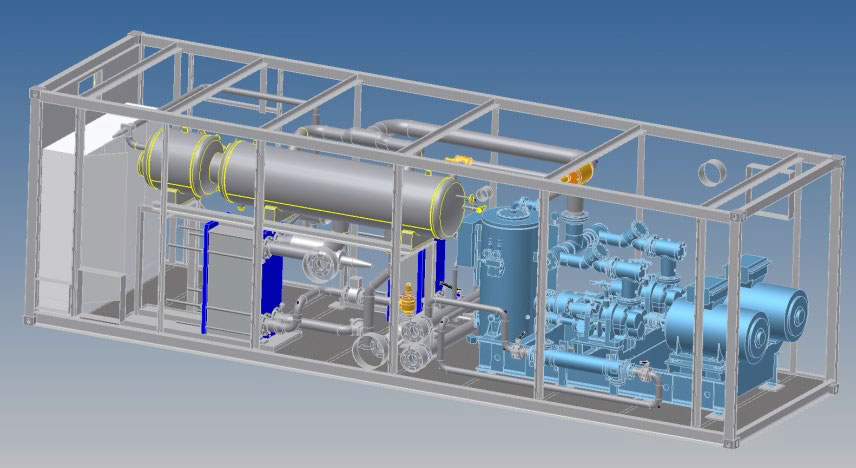

EXAMPLE CO2 / PROPANE CASCADE COOLING SYSTEM

The 40' special container houses a complete CO2 / Propane cascade cooling system, which is used for cooling a refrigerant recovery system in the chemical industry. The system provides a maximum CO2 total cooling capacity of 2 x 124 kW (at –50°C).

Since the system is located in Zone 1, a sufficiently large expansion tank has been provided. This serves to prevent overpressure in the low-temperature stage during standby.

The system is designed according to ATEX and complies with the Ex marking II 2 G / IIC T3.

- Dimensions: approx. 12.2 x 3.0 x 3.2 m (L x W x H)

- Weight: 24 tons (without filling)

Air-cooled R404A compound refrigeration system

The temperature range extends from -20° C to +10° C. In the various rooms, sorting, packaging, storage, and shipping of crab meat take place.

The refrigeration system is also used for permanent room air conditioning.

With the help of the air-cooled R404A compound refrigeration system, 10 working and storage rooms are maintained at different temperatures.

- Dimensions: approx. 12.2 x 2.4 x 2.6 m (L x W x H)

Example MOBILE NH3 REFRIGERATION SYSTEM

This special design as a 30' machine container is used to house the chilled water unit, the supply and return distributors, the water/brine pump, and the control panel.

The air-cooled condenser is integrated into the open container section. This mobile rental refrigeration unit can be installed by ARCTOS at short notice.

Depending on the refrigerant and temperature, the cooling capacity ranges from 120 kW to 500 kW.

- Dimensions: approx. 9.3 x 3.0 x 3.2 m (L x W x H)

- Weight: approx. 14,500 kg (total weight without media filling)

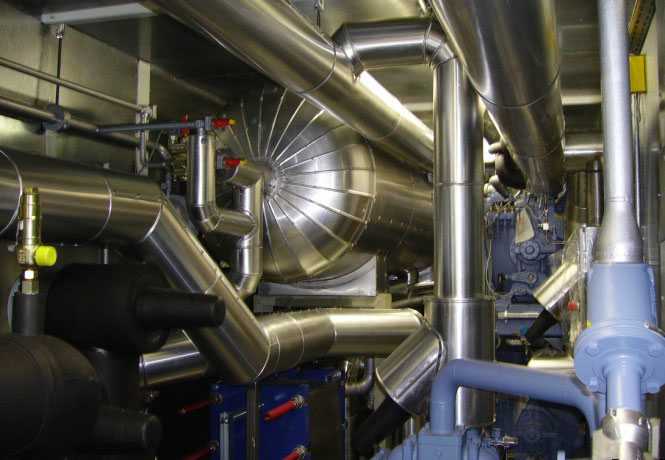

NH3-REFRIGERATION SYSTEM WITH ICE STORAGE

The NH3 refrigeration system is used for cooling ice water, which is required in the working process.

The entire refrigeration system is installed in a soundproofed 40' shipping container and generates a cooling capacity (NH3) of 280 kW at a -10° C evaporation temperature.

The condenser was installed on-site on the roof of the container.

- Dimensions: approx. 12.2 x 2.44 x 2.6 m (L x W x H)

NH3 REFRIGERATION SYSTEM FOR GROUND FREEZING

The above-ground NH3 refrigeration system is used for cooling brine, which is required for ground freezing. For this purpose, channels (freezing probes) are drilled deep into the ground to be frozen and supplied with brine.

The brine, cooled to -38° C, freezes the ground around the drilled freezing probes. Construction work can be carried out without the risk of static damage.

After the completion of construction activities, the refrigeration system can be used at another location. The requirement for this refrigeration system was certification for import and operation in the Russian Federation.

A GOST-R certification (conformity of the export product with Russian quality standards and regulations) and a RosTechNadsor certification (operating permit for the use of technical equipment in Russia) were obtained.

- Dimensions: approx. 10.4 x 3.0 x 3.2 m (L x W x H)

CO2 / NH3 - CASCADE REFRIGERATION SYSTEM

The CO2 / NH3 cascade refrigeration system is used for cooling a refrigerant brine (CaCl2). The refrigerant, cooled to up to -45°C, is used for freezing soil (frost bodies), among other things, for crossheading in tunnel construction.

After the completion of the construction work, the system can easily be disassembled and transported to another location due to its mobile design.

The chosen design as a cascade refrigeration system allows cooling down to -50°C if needed. This provides virtually unlimited applications.

- Dimensions: approx. 12.2 x 2.44 x 2.90 m (L x W x H)