Single-stage NH3 refrigeration system for cooling CaCl2 to +2°C

The customer's objective of receiving an energy-optimized refrigeration system is an increasingly common requirement for ARCTOS in today's market.

This goal is taken into account by ARCTOS as early as the proposal phase and is consistently pursued through to commissioning, during which the optimization of operating parameters is carried out.

The task of designing an energy-efficient system, providing redundant refrigeration supply, manufacturing the system, transporting it to the customer, on-site assembly, and commissioning is implemented by ARCTOS and is integrated into the system concept.

Date: 11/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Chemical and Petrochemical Industry

In the single-stage NH3 refrigeration system, a high COP (coefficient of performance: thermal efficiency) is achieved through an energy-efficient condensation temperature of +32°C and the variable frequency drive (VFD)-controlled compressor operation.

The requirement for 100% availability is met by the redundant design of compressors and heat exchangers. This allows most maintenance and inspections to be carried out without disrupting operations.

The specification of the CaCl2 (chloride brine) solution receives special consideration in the selection of components and materials due to its high corrosiveness. For instance, the NH3 evaporator was selected with a titanium design.

| Refrigerant | NH3 (R717) |

|---|---|

| Refrigerant quantity | max. 400 kg |

| Cooling capacity Q0 | 2 x 435 kW |

| Maximum allowable operating pressure | 16.0 / 21.0 bar (ND / HD) |

| Evaporation temperature | -1°C |

| Coolant | 35% calcium chloride CaCl2 (chloride brine) |

| Coolant inlet t1 | +8°C |

| Coolant outlet t2 | +2°C |

| Condensation temperature | +32°C |

| Cooling medium | Air (evaporative condenser) |

| Compressor manufacturer and type | Mayekawa, reciprocating compressor, single-stage with VFD |

TECHNICAL IMPLEMENTATION

The refrigeration system with 2 x 435 kW brine cooling capacity was manufactured in assemblies on a steel frame for installation in a customer-supplied machine room in Sörup.

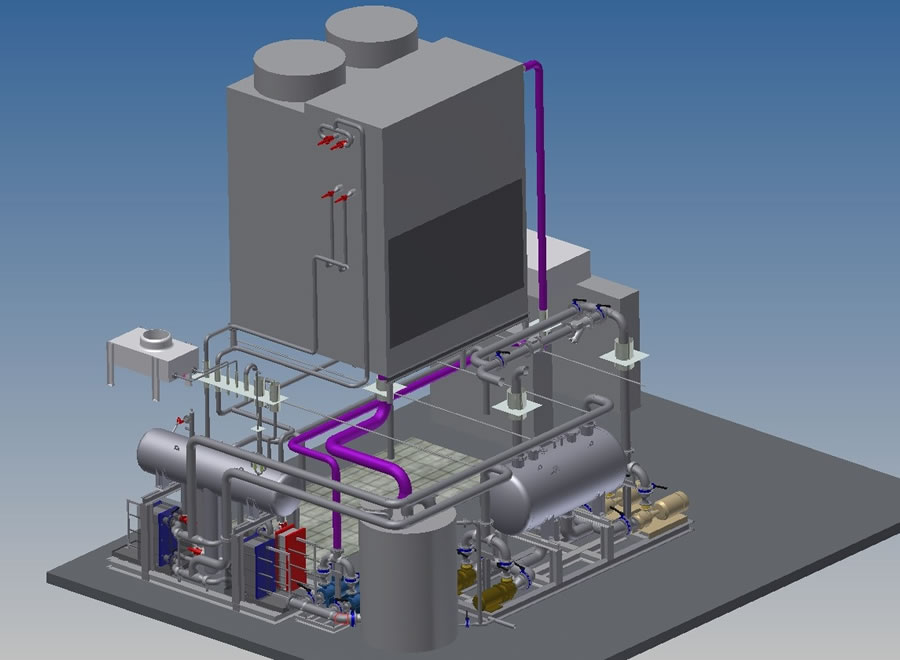

The assembly of the NH3 refrigeration system with its individual components, the evaporative condenser on the roof, and the piping was planned in 3D and implemented accordingly on-site.

FROM 3D PLANNING TO IMPLEMENTATION

The planning of the system is done using the CAD software Autodesk Plant 3D in combination with Inventor, enabling precise planning of the installation, piping, and accurate material takeoffs.

This leads to significant cost savings through a smooth and time-saving on-site system assembly.

Date: 11/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Chemical and Petrochemical Industry