NH3 / R23 Cascade Cooling System for Solar Factory

Sustainable energy supply is gaining increasing importance, not only in Germany.

In the Middle East, a significant photovoltaic industry is developing, which needs to meet enormous cooling demands for its production plants.

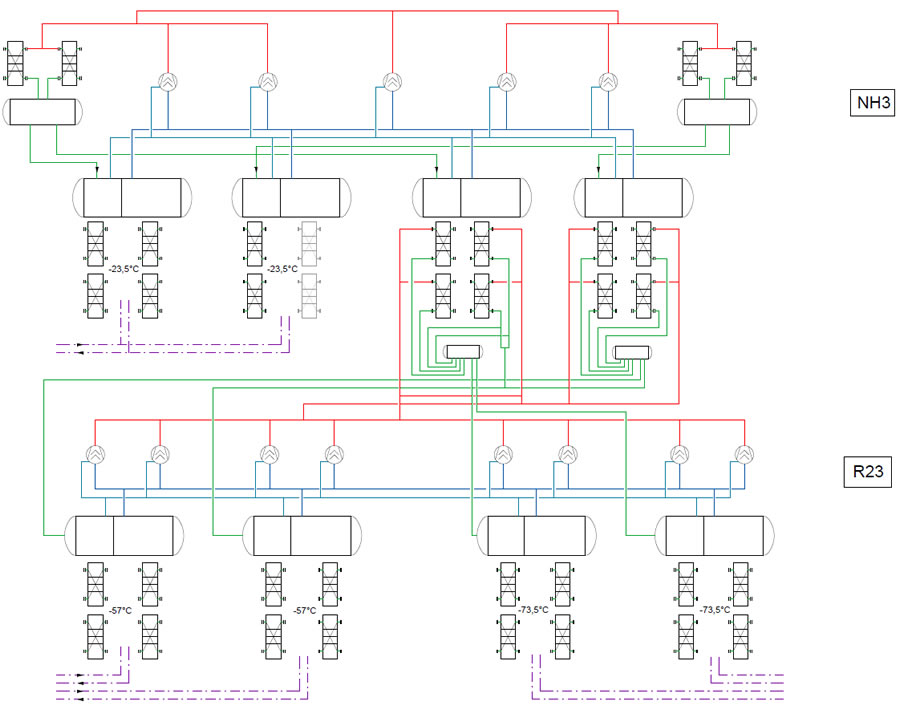

The cooling system supplied by ARCTOS is part of a chemical production facility for the production of high-purity silicon (polysilicon). It provides three stages of cooling for the refrigerant toluene, which is routed into the production facility through a secondary circuit.

Three secondary circuits are to be cooled independently to a toluene temperature of -20.5°C, -53.5°C, and -70.5°C, with a total evaporator capacity of 8.7 MW.

Primary refrigerants NH3 and R23 are connected through a cascade, with each toluene secondary refrigerant circuit being able to operate independently.

| Kältemittel HD-Seite | R717 |

|---|---|

| Kältemittel ND-Seite | R23 |

| Menge Kältemittel R717 | 5.450 kg |

| Menge Kältemittel R23 | 11.500 kg |

| Kälteleistung Q0 | 8,7 MW |

| Kälteträger | Toluol |

| Verdampfungstemperatur | -22,5° C, -56° C, -72,5° C |

| Kondensationstemperatur | +45° C, -20° C, -20° C |

| Kälteträgeraustritt | -20,5° C, -53,5° C, -70,5° C |

| Verdichtertyp | 1-stufiger Schraubenverdichter |

ATEX

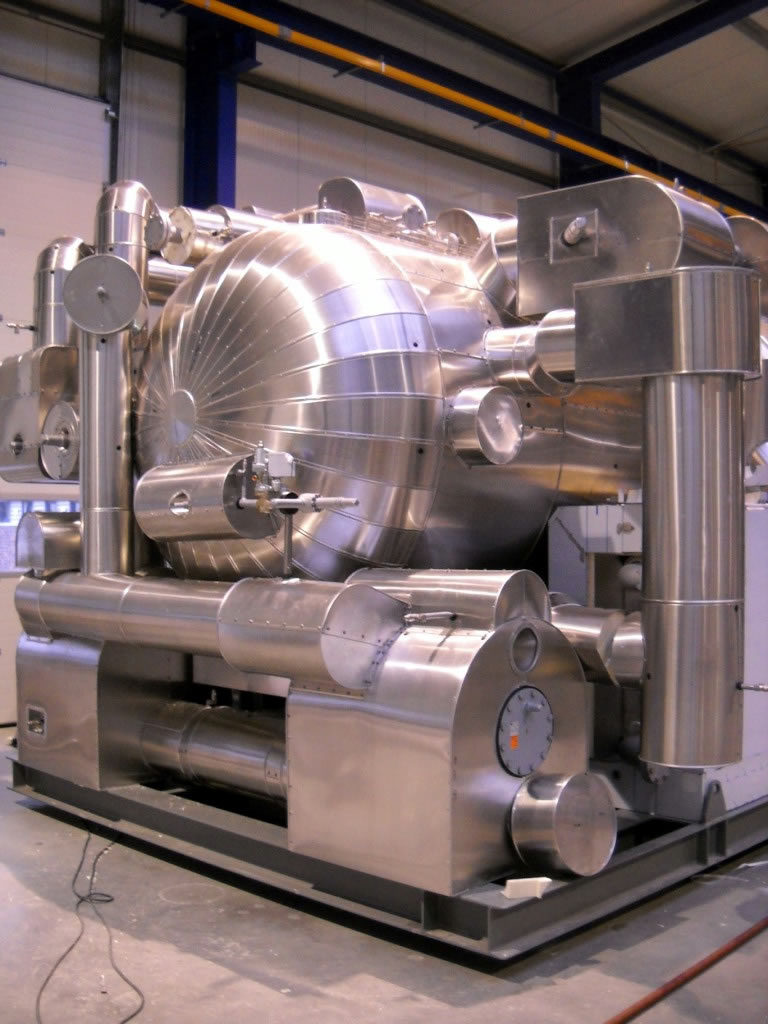

The individual components are prefabricated, internally piped units including insulation and all necessary control and safety devices.

Due to the Ex-Zone 1 caused by the refrigerant, the execution is partially in accordance with the ATEX Directive 94/9/EC (ATEX 95).

REFRIGERATION INSULATION

Extreme climatic conditions and the sometimes very low evaporation temperatures require an elaborate and high-quality execution of the refrigeration insulation.

SCOPE OF SUPPLY AND SERVICES

The scope of supply and services includes, in addition to complete engineering and installation planning, the pipeline planning for main and auxiliary media, including design review, detailed EMSR planning, and software delivery.

The maritime packaging is also part of ARCTOS' responsibilities, as well as on-site supervision of the assembly and mechanical completion of the system components.

After commissioning, a detailed staff training and optimization of the operating settings are carried out. In addition to the documentation, the customer will, of course, receive conformity declarations for all plant units, including CE marking.

Beyond the actual delivery scope, a continuous close cooperation with the customer takes place, for example, in the form of support for HAZOP studies or the creation of the hazard analysis of the entire production plant by considering the interfaces between the refrigeration system and the production plant.