For applications in the food industry (dairies, breweries, meat processing) or in the chemical industry, it is often necessary to provide large cooling capacities within short time frames. This flexibility in the face of extremely fluctuating cooling demand throughout the day is achieved through the use of ice storage systems.

With the stored ice, it is possible to reach ice water temperatures below 1° C. The use of favorable night electricity rates in combination with optimized cooling control also ensures an economically optimal operation.

Date: 11/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Dairies and Creameries | Meat and Fish Processing | Breweries and Beverage Industry

Other advantages of this system are the low refrigerant quantities and the relatively low installed cooling capacity of the system.

Take advantage of ARCTOS's experience to have a custom-tailored ice water cooling system designed to fit your needs.

COOLING CARRIER WATER

The good thermal capacity of ice water provides high cooling in a short time for ice water cooling. Limits are set by the physical properties of water: the coolant can only be cooled down to near 0° C.

ADVANTAGES OF AN ICE WATER STORAGE SYSTEM

- Flexibility with extremely fluctuating cooling demands

- More economical use of favorable night electricity rates

- Low refrigerant quantities

- Relatively low installed cooling capacity

| Refrigerant: | NH3 (R717) |

|---|---|

| Refrigerant Quantity: | 350 kg |

| Cooling Capacity Q0: | 280 kW |

| Evaporation Temperature: | -10° C |

| Condensation Temperature: | +43° C |

| Cooling Carrier: | Chilled Water |

| Cooling Carrier Temperature: | 0.4°-1° C |

| Ice Storage Capacity: | 4,300 kWh |

| MAIN COMPONENTS | |

| Compressor Manufacturer and Type: | Grasso DD-5A Duo Screw Compressor |

| Ice Water Silo with Spraying: | BUCO Spraying Film Ice Generator |

| Cooling Capacity Q0: | 280 kW |

| NH3 Evaporator: | BUCOdelot Bee |

| Air-Cooled NH3 Condenser: | Thermofin 080 |

EXAMPLE SPRAY FILM ICE GENERATOR

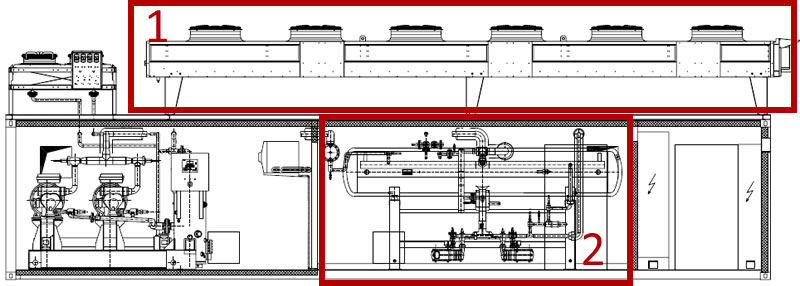

The NH3 refrigeration system is used to cool ice water, which is required in the working process. The ice water, cooled to 1° C, is stored in a 140,000-liter tank.

The entire refrigeration system is installed in a soundproofed 40' shipping container.

A spray film ice generator is responsible for producing crushed ice with the help of the refrigerant in the heat exchanger plates, which is then stored in the ice container.

After the melting process (discharge), the PLC-controlled refrigeration system automatically begins to recharge the ice storage.

Date: 11/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Dairies and Creameries | Meat and Fish Processing | Breweries and Beverage Industry