The chemical industry is a demanding customer group with high requirements for refrigeration systems. To meet these demands, ARCTOS develops a refrigeration solution for your process in collaboration with you and carries out an individual system design.

In doing so, requirements such as high availability, short maintenance and inspection intervals, the highest safety standards, energy efficiency guidelines, and the environmentally responsible selection of refrigerants are taken into account.

Date: 11/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Chemical and Petrochemical Industry

Beyond the actual scope of delivery, there is continuous close cooperation with the customer, such as support in HAZOP studies or in the creation of the hazard analysis for the entire production plant by considering the interfaces between the refrigeration and production systems.

MANUFACTURING STANDARDS

Every system leaving the Sörup plant undergoes an EU individual inspection according to DGRL 2014/68/EU and is marked with the CE0045 label. Furthermore, ARCTOS is a specialist company according to WHG with implementation according to AwSV and its own quality management system.

To meet the quality and safety standards of many clients, ARCTOS has voluntarily been certified according to SCC** (Safety Certificate Contractors).

If explosion protection is required, an assessment according to the European Directive 2014/34/EU will be carried out.

ARCTOS Industrial Refrigeration AG has achieved the "silver recognition level" on the EcoVadis sustainability assessment platform, which evaluates environmental and social practices of companies.

The planning of refrigeration systems is carried out using CAD software Autodesk Plant 3D in combination with Inventor, allowing for precise planning of installation, piping, collision checks, and accurate mass calculations.

Scope of Delivery and Services

- Complete engineering, including installation planning

- Piping design for main and auxiliary media, including design review

- On-site assembly and mechanical completion

- EMSR detailed planning and execution

- Acceptance of systems in Sörup and at the installation site

- Supervision of assembly and mechanical completion on-site

- Shipping, including (seaworthy) packaging

- Commissioning with detailed personnel training

- Optimization of operational settings

- Documentation with declarations of conformity, including CE marking

- Maintenance and service contracts for system support

- Through ARCTOS Maintenance GmbH, proper provision of personnel is also possible

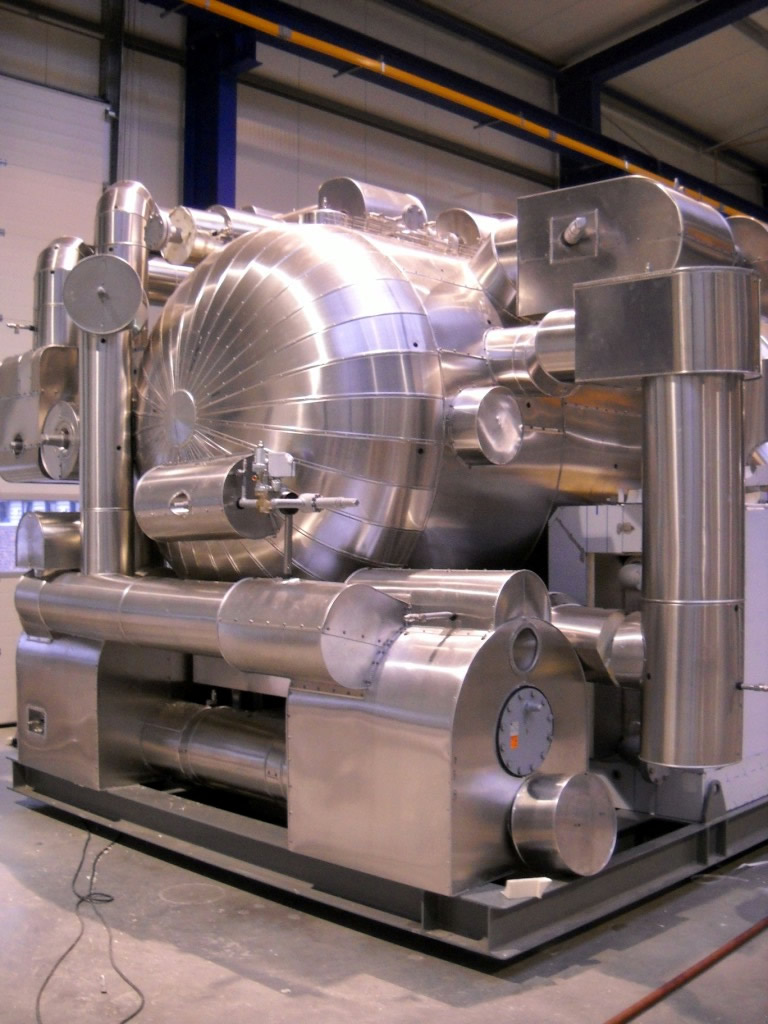

NH3 / R23 Cascade Refrigeration System for Cooling Toluene to -20.5° C, -53.5° C, and -70.5° C

The refrigeration system supplied by ARCTOS is part of a chemical production facility for the production of high-purity silicon (polysilicon).

It provides three stages of cooling for the refrigerant toluene, which is circulated through a secondary circuit to the production plant. This way, three independent secondary circuits are cooled to toluene temperatures of -20.5° C, -53.5° C, and -70.5° C, with a total evaporator capacity of 8.7 MW.

The primary refrigerants NH3 and R23 are connected via a cascade, with each secondary refrigeration circuit able to operate independently.

The individual components are prefabricated, internally piped units, including insulation and all necessary switching and safety devices.

Due to the explosion-proof zone 1 caused by the refrigerant, the system is partially executed according to the ATEX Directive 94/9/EC (ATEX 95).

2-Stage NH3 Refrigeration System for Cooling Dichloromethane to -42°C

The 2-stage refrigeration system was developed and manufactured for a chemical industry company, in accordance with the requirements for high availability and safety standards. The goal was to cool dichloromethane in two separate refrigeration circuits in a 1/3 to 2/3 ratio to -42°C.

To achieve the required evaporation temperature of -44°C, but without using a complex cascade system, the NH3 system was designed to operate in a vacuum range (approximately 0.6 bar(a)).

This required specific construction measures that had to be carefully considered during the system design.

| Refrigerant: | NH3 (R717) / R23 |

|---|---|

| Refrigerant quantity R717: | max. 5,450 kg |

| Refrigerant quantity R23: | max. 11,500 kg |

| Total cooling capacity Q0: | 8.7 MW |

| Refrigerant: | Toluene |

| Evaporation temperatures: | -22.5° C, -56.0° C, -72.5° C |

| Condensation temperatures: | +45.0° C, -20.0° C, -20.0° C |

| Refrigerant outlet: | -20.5° C, -53.5° C, -70.5° C |

| Compressor manufacturer and type: | GEA-Grasso, screw compressor |

| ATEX specification: | Zone 1 T1 IIC |

To achieve the low evaporation temperature, the NH3 screw compressors are designed in a 2-stage configuration.

The ND and HD stages are integrated into a single unit and feature an ECO intermediate feed for additional energy efficiency.

The refrigeration system is an NH3 system with 2 redundant refrigerant compressors, due to availability, with separate 500V electric motors that are operated with frequency inverters.

| Refrigerant: | Propene R1270 |

|---|---|

| Refrigerant quantity: | 240 kg |

| Maximum allowable operating pressure: | 16.0 / 25.0 bar (ND / HD) |

| Evaporation temperature: | -10° C |

| Condensation temperature: | +39° C |

| Max. total cooling capacity: | 2 x 227 kW (at -10° C) |

| Compressor manufacturer & type: | GEA-Grasso, 2 x piston compressors Grasso 610 |

| Condensation requirement: | 2 x 298 kW |

| Cooling water inlet / outlet: | +31° C / +36° C |

| Refrigerant: | CO2 R744 |

| Refrigerant quantity: | 1,100 kg |

| Maximum allowable operating pressure: | 25.0 / 40.0 bar (ND / HD) |

| Evaporation temperature: | -50° C |

| Condensation temperature: | -7° C |

| Max. total cooling capacity: | 2 x 124 kW (at -50° C) |

| Compressor manufacturer & type: | GEA-Grasso, 2 x piston compressors Grasso 45HP |

| Condensation requirement: | 2 x 164 kW |

| ATEX SPECIFICATION | |

| Device category: | II 2 G (Zone 1, Gas) |

| Ignition group: | II B H2 |

| Temperature class: | T3 |

| Surface temperature: | +200° C |

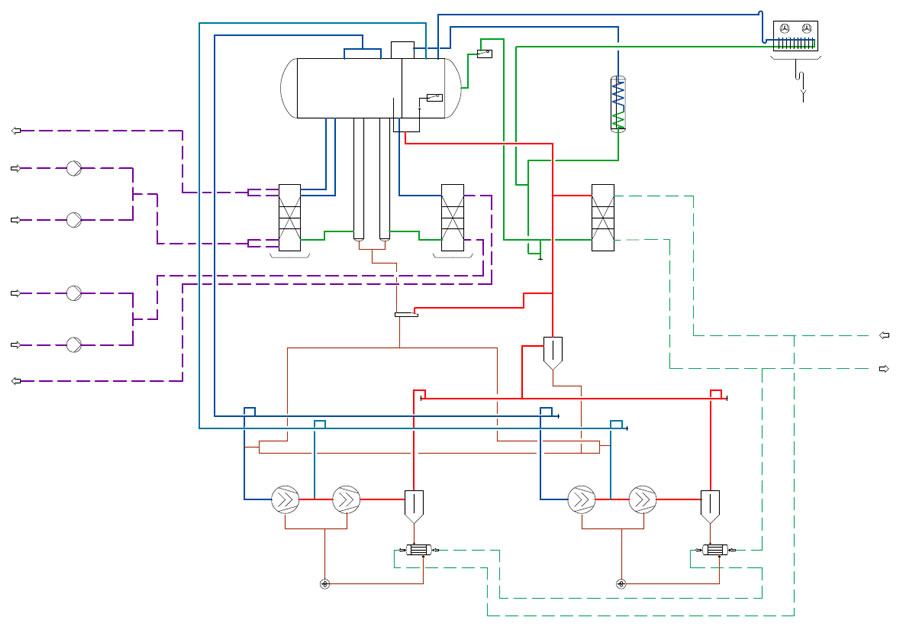

CO2 / Propene Cascade Refrigeration System for Cooling MEK to -35°C

A CO2 / propene cascade refrigeration system is used to cool a synthesis stream of organic solvents (Methyl Ethyl Ketone, MEK).

In the cascade refrigeration system built by ARCTOS, two refrigeration machines are integrated into each cascade stage.

The evaporator of the upper cascade stage (propene) is also the condenser of the lower cascade stage (CO2). The liquid CO2 cools the chemical process to -50°C through its evaporation.

At temperatures of -50°C, the technical components must meet high standards, and for explosion-protected systems like this one (device category II 2 G (Zone 1, Gas), ignition group II B H2), stringent safety measures must be implemented.

1-Stage NH3 Refrigeration System for Cooling CaCl2 to +2°C

This 1-stage NH3 refrigeration system was designed for a carbon fiber manufacturer.

The refrigeration system achieves a high COP value (coefficient of performance = thermal efficiency) through an energetically favorable condensation temperature of +32°C and frequency inverter-controlled compressor operation.

The requirement for 100% availability is met by the redundant design of the compressors and heat exchangers. The specification of the brine CaCl2 (calcium chloride) is given special consideration in the selection of components and materials due to its high corrosiveness.

For example, the NH3 evaporator was chosen with a titanium construction. The refrigeration system with 2 x 435 kW brine cooling capacity was manufactured in modular units on steel frames for installation in a customer-supplied machine room in Sörup.

The installation of the NH3 refrigeration system with its individual components, the evaporative condenser on the roof, and the piping was planned in 3D and carried out accordingly on-site.

| Refrigerant: | NH3 (R717) |

|---|---|

| Refrigerant quantity: | max. 400 kg |

| Cooling capacity Q0: | 2 x 435 kW |

| Maximum allowable operating pressure: | 16.0 / 21.0 bar (ND / HD) |

| Evaporation temperature: | -1° C |

| Refrigerant: | 35% Calcium chloride CaCl2 (calcium chloride brine) |

| Refrigerant inlet t1 / outlet t2: | +8.0° C / +2.0° C |

| Condensation temperature: | +32° C |

| Cooling medium: | Air (evaporative condenser) |

| Compressor manufacturer and type: | Mayekawa, reciprocating compressor, 1-stage with frequency inverter |

Date: 11/2022 | E-Mail | +49 (0)4635 - 292 82-0

Industry: Chemical and Petrochemical Industry